No chemical additives baby wet Wipes

Product introduction

Let you know more

NO CHEMICAL ADDITIVES BABY WIPES

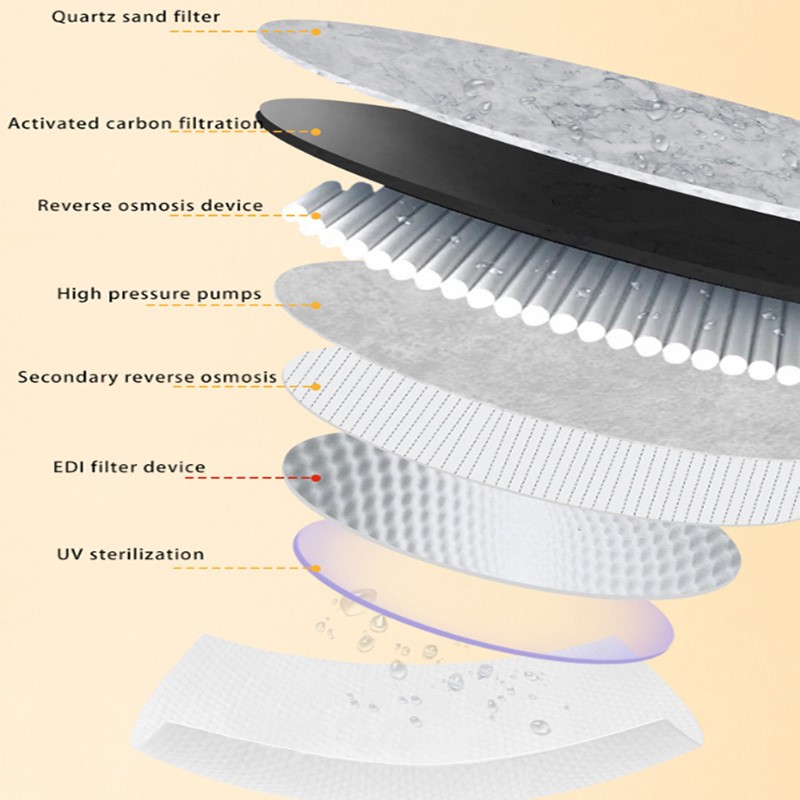

Ensure the best quality of baby wipes

The following process should be necessary:

| Raw material | spunlace non-woven(pearlet、plain),RO Pure water、EEDI ultrapure water  |

| Product size | 120mm*140mm 155mm*200mm 140mm*150mm 170mm*180mm 200mm*240mm 150mm*200mm 200mm*150mm 140mm*200mm 180mm*150mm 200mm*200mm 130mm*180mm 150mm*180mm |

| Packaging size | 430*360*430mm |

| Packaging type | 80pcs/bag(24bag/ctn)、70pcs/bag(24bag/ctn)、48pcs/bag(20bag/ctn)、40pcs/bag(48bag/ctn)、10pcs/bag(200bag/ctn)、12pcs/bag(150bag/ctn)、64pcs/bag(46bag/ctn),1100Ctns/20ft container,2300Ctns/40HQ |

| Delivery time | 5-15days |

| Production capacity | 5 million packs/month |

| MOQ | 25000-100000bags |

Advantage

Baby Wet WipesCare for hands and mouth

Safe and non-allergenic formula

1 . No formaldehyde

2.fragrance free

3 . No fluorescent agent

4 . Microbiologicallyqualified

1.enlarge and thicken, clean more comprehensively

2.More comfortable and convenient to use, just right moisture content

3.Balance the effect of decontamination and preservation

Close to skin PH valueCare for baby's delicate skin

1.EDI pure water has evolved through 7 times of high penetration.

2.EDI pure water extracted by permeation technology is far more pure than pure water and can be consumed directly

Quality Assurance

While cleansing and moisturizing the skin, it will not damage the natural weak acid protective layer

Authoritative certification, can pass FDA,MSDS,GMPC,BPA certification ,quality assurance

Good products can withstand authoritative quality inspections, so you can buy them with confidence and use them comfortably.

To make sure best quality of the baby wipes

The non-woven fabric machine is used to make the surface of the fabric smooth and smooth. Spunbond, spunlace, and airlaid nonwovens will be common choices for fabrics. The non-woven fabrics used in wet wipes include baby wipes, makeup wipes, alcohol wipes, disinfection wipes, household wipes, etc. Dot patterns, embossing, straight patterns, crosses, meshes, and EF textures will be selected.

To make sure best quality of the baby wipes

The process of making dry and wet wipes takes time, and frequent and careful measurement. The final distribution of wet wipes depends on various types of processes to adjust knives, regardless of the number and quality of knives. Used in the production of fully automatic wet tissue bags.

a. Make sure that the folded wipes are even, and it is important to adjust each row of fabric to a straight line.

b. Mainly the distance between the wiping line and the centerline plate and the fabric connection between the rollers should not be blocked.

c. The soft packaging of wet wipes should be evenly distributed on both sides.

d. The lid and sticker should be smoothly attached to the pouch of wet wipes.

To make sure best quality of the baby wipes

The special formula for clean water treated by the RO treatment system needs to be professionally made, and the tightness of the soft pack must be enough to moisten the wet wipes, otherwise the wet wipes will turn yellow and the wet wipes will breed bacteria.

BPA-free packaging is important for environmentally friendly baby wipes, and to ensure that the liquid is kept in the small bag of wipes for as long as possible. Aluminum film is used for packaging. The sealing process in the production of wet wipes is very important.